Best Air Compressor Water Filter Parker

Nowadays, there are so many products of air compressor water filter parker in the market and you are wondering to choose a best one. You have searched for air compressor water filter parker in many merchants, compared about products prices & reviews before deciding to buy them.

You are in RIGHT PLACE.

Here are some of best sellings air compressor water filter parker which we would like to recommend with high customer review ratings to guide you on quality & popularity of each items.

22,717 Reviews Scanned

NANPU Air Filter Pressure Regulator Lubricator Dryer Gauge Kit 1/4" NPT Water/Oil Trap Separator 3 in 1 Twin (0-150psi)

NANPU 3 in 1 Twin Air Filter Pressure Regulator Gauge Kit 1/4″ Water/Oil Trap Separator offer you best usage experience ever.

Installation and Operating:

1. Please cleaning the port and fitting before installing, avoiding bringing dirty thing to the air path.

2. Pay attention to direction of air flow and arrow pointing on body if match, minding port and tooth type if correct.

3. Adjustment of pressure: Pull up the knob of adjustment of pressure up, clockwise rotation, pressure is rising. Anticlockwise rotation, pressure is down. Watch the air gauge and point range and adjust the required pressure, then press the button to the lock status.

4. Water bowl excretion. When it is no air pressure, water bowl will automatic excrete. When it has air pressure, the drainage column will rise. Water bowl excreted, releasing the drainage column after drainage finished, then drainage column will automatic rebound, drainage ended. When the water level is beyond upper limit, please drainage. Otherwise that will cause poor dehumidification.

5. Adjustable oil: Clockwise rotated needle valve, oil dropped will reduce. Anticlockwise rotated needle valve, oil dropped will increase. After adjusted air flow and set needle valve, air flow and oil dropped will increase, air flow and oil dropped will reduce. 6. Refueling method: You can open air path then refueling oil. Anticlockwise rotates refueling screw, refueling capacity does not exceed 80% of bowl. After refueling, please lock refueling screw.

Notice:

Please be careful to use a wrench to tighten the fitting. It is normal if there are extra threads, you can feel free to use. The first installation may have an excretion reaction(Not leakage, for the first time the internal pressure is different from the outside, it is necessary to discharge the excess air first). In this case, please wait for a while.

HEAVY DUTY 3/4" IN-LINE COMPRESSED AIR PRESSURE REGULATOR, 7 TO 215 PSI ADJUSTABLE, BRACKET, GAUGE

- HEAVY DUTY 3/4″ FEMALE NPT IN LINE COMPRESSED AIR PRESSURE REGULATOR

- 250 PSI MAX INPUT PRESSURE, 215 MAX OUTPUT PRESSURE, WALL MOUNTING BRACKET & GAUGE INCLUDED

- ADJUSTABLE FROM 7 PSI TO 215 PSI, 140 SCFM FLOW RATE

- HIGH IMPACT LOCKING COMPOSITE KNOB

- 3/4″ NPT OUTSIDE THREAD DIAMETER IN INCHES 1.05″ LINEAR

HEAVY DUTY HIGH FLOW 3/4" IN-LINE COMPRESSED AIR PRESSURE REGULATOR, 7 TO 215 PSI ADJUSTABLE, BRACKET, GAUGE

- HEAVY DUTY 3/4″ FEMALE NPT IN LINE COMPRESSED AIR PRESSURE REGULATOR

- 250 PSI MAX INPUT PRESSURE, 215 MAX OUTPUT PRESSURE, WALL MOUNTING BRACKET & GAUGE INCLUDED

- ADJUSTABLE FROM 7 PSI TO 215 PSI, 160 SCFM FLOW RATE

- HIGH IMPACT LOCKING COMPOSITE KNOB

- 3/4″ NPT OUTSIDE THREAD DIAMETER IN INCHES 1.05″ LINEAR

Parker R364-02C Regulator, Relieving Type, 0-125 psi Pressure Range, No Gauge, 10 scfm, 1/4" NPT

- Diaphragm operated for fast operation

- Large diaphragm to valve area ratio for precise regulation and high flow capacity

- Balanced valve design for precise regulation

- Available with a manifold mount to minimize plumbing

- Suitable for low temperature applications

Parker 14F15BB Compressed Air Filter, Removes Particulate, Polycarbonate Bowl, Auto Pulse Drain, 5 Micron, 24 scfm, 1/4" NPT

Parker R119-06CG Regulator, 0-125 psi Pressure Range, Gauge, 300 scfm, 3/4" NPT

Parker 07E34A13AC One-Unit Combo Compressed Air Filter/Regulator, 1/2" NPT, Metal Bowl with Sight Gauge, Manual Drain, 40 Micron, 90 scfm, Relieving Type, 2-125 psi Pressure Range, No Gauge

- Parker 07E standard series compressed air filter/regulator for water and particulate removal, and air pressure control

- Single-unit, integral, “piggyback” filter/regulator for space-saving installations

- Relieving-style regulator exhausts excess pressure for increased performance and safe operation

- Removable, non-rising knob for tamper resistance

- Male National Pipe Taper (NPT) threads for connecting to female threaded pipes

This Parker 07E standard series compressed air filter/regulator is for water and particulate removal, and air pressure control. This filter is a single-unit, integral, “piggyback” filter/regulator for space-saving installations and has a relieving-style regulator to exhaust excess pressure for increased performance and safe operation. It has a removable, non-rising knob for tamper resistance and male National Pipe Taper (NPT) threads for connecting to female threaded pipes.

Compressed air filters remove pollutants and submicronic contaminants from clean air in compressed air handling and preparation systems. Clean compressed air provides and controls energy, conveys materials, and is critical to the safe operation of equipment in many industries. Compressed air filters remove particulates (dirt), oil, water, and oil vapor. They can be combined with other units, integrating with either a regulator, which controls excess pressure for better performance, or a lubricator, which adds oil mist to the air, or both. They are typically constructed of metal, such as zinc or type 316 stainless steel, or transparent polycarbonate, and are available with optional indicators, gauges, and drain configurations depending on the application. Compressed air filters are used in a wide range of applications, including food processing, electronics, health care, and instrumentation, among others.

Parker Hannifin manufactures electromechanical, hydraulic, and pneumatic motion technologies and systems. The company, founded in 1918 and headquartered in Cleveland, OH, provides fluid handling, filtration, sealing and shielding, climate control, process control, and aerospace technologies.

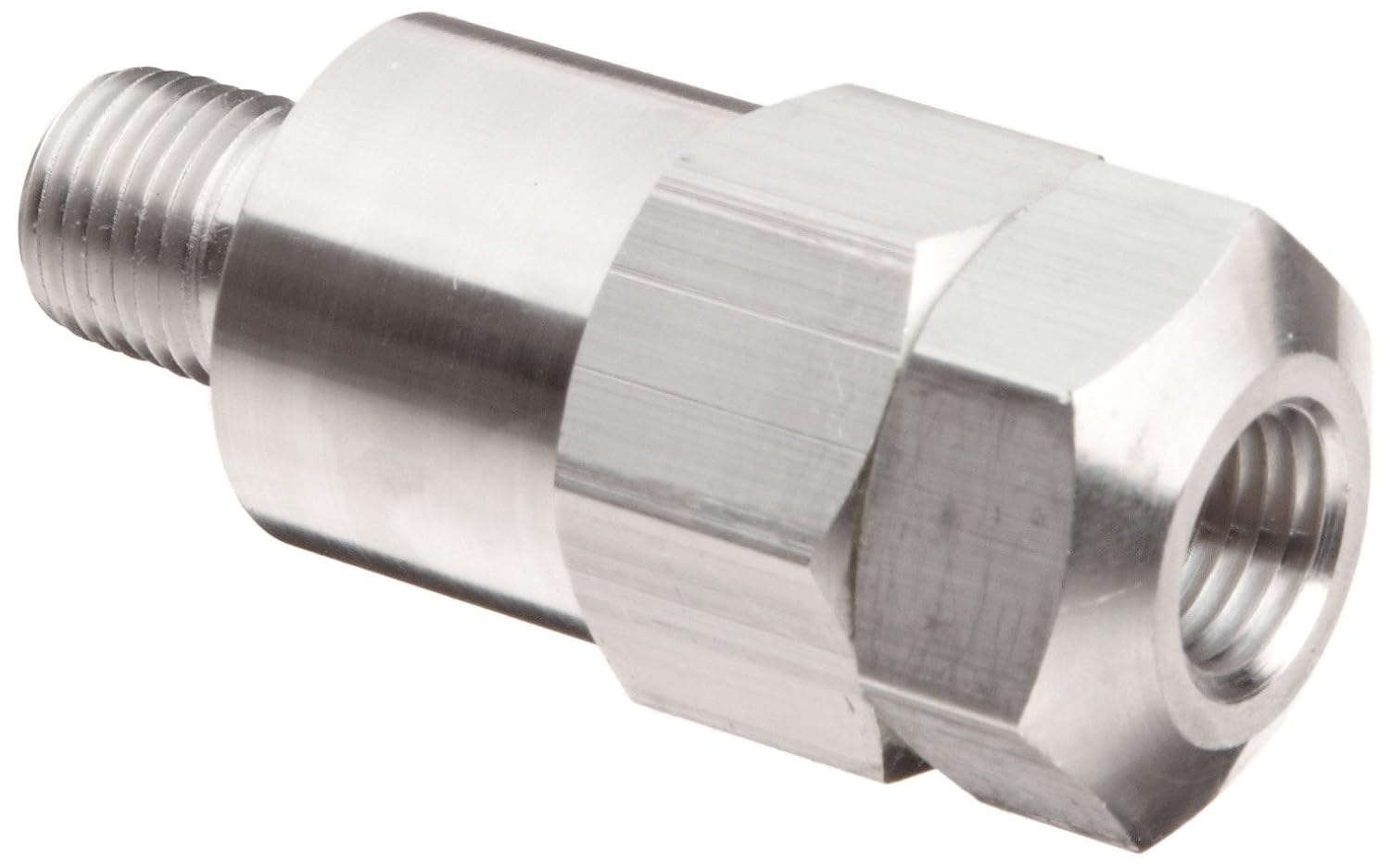

Parker 02F1BA Compressed Air Filter, 5 Micron, 17 scfm, 1/4" NPT/BSPT

Parker 06F32AC Compressed Air Filter, Removes Particulate, Polycarbonate Bowl with Metal Bowl Guard, Manual Drain, 40 Micron, 85 scfm, 1/2" NPT

- Parker 06F compact series compressed air filter for water and particulate removal

- Polycarbonate bowl resists grease, oil, detergent, and most inorganic acids, and has very high impact resistance

- Operating temperatures range from 32 to 125 degrees F

- Large filter element surface for low pressure drop and increased element life

- Deflector plate with shroud swirls the air stream ensuring water and dirt separation

This Parker 06F compact series compressed air filter helps remove water and solid particulates from a compressed air system. This filter has a polycarbonate bowl, which resists grease, oil, detergent, and most inorganic acids, and has very high impact resistance. Its operating temperatures range from 32 to 125 degrees F, and it has a 40 micron rating for contaminant and particle reduction. Its large filter element surface allows for low pressure drop and increased element life, and a unique deflector plate with a shroud swirls the air stream, ensuring that water and dirt are properly separated. It has male National Pipe Taper (NPT) threads for connecting to female threaded pipes. This filter is suitable for use in manufacturing and automated production environments.

Compressed air filters remove pollutants and submicronic contaminants from clean air in compressed air handling and preparation systems. Clean compressed air provides and controls energy, conveys materials, and is critical to the safe operation of equipment in many industries. Compressed air filters remove particulates (dirt), oil, water, and oil vapor. They can be combined with other units, integrating with either a regulator, which controls excess pressure for better performance, or a lubricator, which adds oil mist to the air, or both. They are typically constructed of metal, such as zinc or type 316 stainless steel, or transparent polycarbonate, and are available with optional indicators, gauges, and drain configurations depending on the application. Compressed air filters are used in a wide range of applications, including food processing, electronics, health care, and instrumentation, among others.

Parker Hannifin manufactures electromechanical, hydraulic, and pneumatic motion technologies and systems. The company, founded in 1918 and headquartered in Cleveland, OH, provides fluid handling, filtration, sealing and shielding, climate control, process control, and aerospace technologies.

Parker 07F48AC Compressed Air Filter, Removes Particulate, Metal Bowl with Sight Gauge, Auto Float Drain, 40 Micron, 145 scfm, 3/4" NPT

- Parker 07F standard series compressed air filter with sight gauge for water and particulate removal

- Metal bowl is made of zinc, which is hard, brittle, and a fair conductor of electricity

- Operating temperatures range from 32 to 125 degrees F

- Large filter element surface for low pressure drop and increased element life

- Deflector plate with shroud swirls the air stream ensuring water and dirt separation

This Parker 07F standard series compressed air filter with sight gauge helps remove water and solid particulates from a compressed air system. This filter has a metal bowl made of zinc, which is hard, brittle and a fair conductor of electricity. Its operating temperatures range from 32 to 125 degrees F, and it has a 40 micron rating for contaminant and particle reduction. Its large filter element surface allows for low pressure drop and increased element life, and a unique deflector plate with a shroud swirls the air stream, ensuring that water and dirt are properly separated. It has male National Pipe Taper (NPT) threads for connecting to female threaded pipes. This filter is suitable for use in manufacturing and automated production environments.

Compressed air filters remove pollutants and submicronic contaminants from clean air in compressed air handling and preparation systems. Clean compressed air provides and controls energy, conveys materials, and is critical to the safe operation of equipment in many industries. Compressed air filters remove particulates (dirt), oil, water, and oil vapor. They can be combined with other units, integrating with either a regulator, which controls excess pressure for better performance, or a lubricator, which adds oil mist to the air, or both. They are typically constructed of metal, such as zinc or type 316 stainless steel, or transparent polycarbonate, and are available with optional indicators, gauges, and drain configurations depending on the application. Compressed air filters are used in a wide range of applications, including food processing, electronics, health care, and instrumentation, among others.

Parker Hannifin manufactures electromechanical, hydraulic, and pneumatic motion technologies and systems. The company, founded in 1918 and headquartered in Cleveland, OH, provides fluid handling, filtration, sealing and shielding, climate control, process control, and aerospace technologies.

Conclusion

By our suggestions above, we hope that you can found air compressor water filter parker for you.Please don’t forget to share your experience by comment in this post. Thank you!